BLOG

On-Time Delivery Starts Early: Protecting Your Timelines With Scheduling Visibility

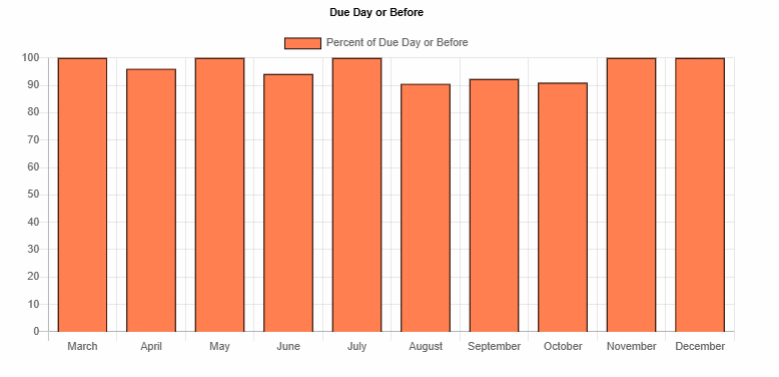

Some principles are just as important in both everyday life and manufacturing. One we’ve always followed at Focused on Machining is simple: don’t delay hard conversations. We’re proud of our 95% on-time delivery rate in our Colorado machine shop, but even in our shop, there are projects that might fall slightly behind plan. Waiting tends to only make outcomes worse, especially when lead times and schedules are on the line.

If a project might be delayed, we have built our shop to have the visibility to know that weeks or even months in advance. We always reach out early, explain what we’re seeing, and work with you to decide the best path forward.

On-Time Delivery Is a Priority at FOM

On-time delivery is central to how we plan and manage our work every single day. As an AS9100 machine shop, our baseline internal target is 90% on-time delivery. However, we never settle for that goal; we consistently exceed that benchmark, and in many months are able to achieve 100%.

Still, manufacturing is complex, and the unexpected happens all the time. Processes shift, materials arrive late, or parts slip at an outside vendor. But helping you see the risk early can make the difference between costly delays and smooth adjustments.

In fact, one thing we’ve heard many times from prime contractors is that they’re surprised how far in advance we can identify a risk. For example, in a recent conversation with ULA, we reviewed parts that were due in four months. Based on our schedule visibility, we told them there was a risk of a slight delay. But they said the advance notice allowed them to evaluate their options and avoid any sort of last-minute scramble. It’s one part of our shop’s commitment to customer service.

Advanced Tech and Granular Planning Create Visibility

That level of visibility comes from planning our projects to an extremely granular level of detail. In ProShop ERP, we create schedules that account for every stage of our work, from planning and machining through inspection, outside processing, and shipping. For instance, we don’t just lump together every step of shipping into a vague task marked “ship”; instead, we schedule specific steps like reviewing shipping paperwork and wrapping parts for shipment.

At first, that level of detail can seem excessive to some people, but it’s truly critical to staying on track and keeping lead times accurate. For a high-volume job, final packaging and prep can take a full day. If you compress everything into a generic two-hour task, you’re setting yourself up for delays before the job even begins.

What We Do When a Schedule Is at Risk

If a task falls behind its planned date in ProShop, the system alerts us and highlights the projected impact on the final due date. We’ve always built in buffers due to the amount of uncertainty that is natural in manufacturing. But if we see that buffer disappearing, we know it's time to act.

Early visibility allows us to respond with intention. First, we confirm whether the schedule slip is minor enough for us to catch up on, or if it may affect delivery. If we think the risk is real, we alert you immediately to the possibility of late arrival. Then, we review available options together.

If the delay stems from our actions, we always own that and are prepared to implement internal expedites without changing the price. But if a vendor or outside process is the bottleneck, we’ll talk through expediting options and weigh the tradeoff between added cost and delivery. We always want to make sure you can make an informed choice about the best outcome for your project.

Choose a Proactive Manufacturing Partner

These situations are rare, but they do happen. And when they do, transparency is non-negotiable at Focused on Machining.

Trust is built through consistent performance and honest communication. As a machine shop that prides itself on on-time delivery, we treat your deadlines as our own, and back that up with planning and accountability.

If you need a precision machining partner for your next project, request a quote today!

How Our Aerospace Machine Shop Helps Primes Add Approved Suppliers

At Focused on Machining, we take pride in supporting prime contractors with reliable quality and consistent on-time delivery. But being a great aerospace machine shop means going beyond manufacturing, as well.

One way we add value is by helping primes expand their approved supplier lists when bottlenecks begin affecting schedules. In our partnerships with primes like United Launch Alliance (ULA) and Lockheed Martin, we’ve learned that secondary processing from a small list of approved suppliers can add significantly to timelines.

We’ve stepped up to help them add trusted suppliers to their lists. It’s not a simple process, but we believe this proactive support is part of being the best manufacturing partner possible.

The Hidden Bottleneck: Limited Approved Supplier Lists

Many prime contractors maintain approved supplier lists for processes such as plating, finishing, and heat treating. These lists can be important for quality control and compliance, especially in areas like aerospace machining.

However, these lists can sometimes create constraints. The vendors may naturally be busy, especially if they’re serving a large number of precision machine shops all working for the same prime.

We’ve seen situations where a tight supplier list could increase lead times by three to five weeks for secondary processing alone. When that happens, turnaround can take time, even if our machining is extremely efficient.

How We Help Primes Add Qualified Vendors

When we see a potential supplier bottleneck, we reach out to primes to help them qualify additional vendors that we believe will be a strong match. It’s a collaborative effort, and primes sometimes tell us they haven’t had other machine shops help in this way.

We first start a three-way conversation, connecting the prime and the vendor. We often help “translate” for each party. For instance, primes may use internal specification references for certain processes that we understand, but vendors can’t immediately recognize.

From there, we help them understand which specifications the vendor can certify to, what documentation is required, and how the process will proceed moving forward with audits, paperwork, or other steps.

The Outcome: Reduced Lead Times and Lower Risk

This kind of coordination takes real effort, and usually takes three to six months to get a new vendor onto the list. But the long-term payoff for both our shop and the primes can be substantial. It leads to faster turnarounds with trusted vendors and helps to break through a bottleneck.

One success story from recent months is Metal Finishing Company in Wichita, Kansas. We’ve worked with them for plating on ULA projects, and their quality and reliability have stood out. But they weren’t yet approved with ULA for heat treating stainless steel, even though they had the capability to do that work.

We shared our experience with ULA and encouraged them to expand approval into those additional processes, helping to start the conversation with the vendor. They agreed, and it added significant flexibility for future projects.

This type of approval expansion is especially valuable because it can enable the consolidation of multiple processes with one vendor. When a part requires several secondary operations, sending it to multiple vendors can add weeks of handoffs and significant lot fees. Consolidating processes under one roof can significantly reduce cost and shorten lead times.

Supporting You as an Aerospace Machine Shop

Precision machining will always be our core service. But we’re committed to adding value throughout our partnership, whether that means helping you find suppliers, achieving Level 2 CMMC certification early, or communicating proactively to keep your project on track.

Request a quote today and collaborate with a partner that is proactive in supporting your success!

Reduce Schedule Risk With Our Subassembly Services

At Focused on Machining, we’re proud of the precision machining we perform every day. But we know that for prime contractors and aerospace OEMs, excellent parts are only part of the equation. When a program requires multiple components, certified hardware, outside processing, and assembly, coordination can be just as difficult. That’s why our subassembly services are such a critical capability. We send you a complete subassembly that’s ready for the next step, with the documentation that shows it.

Why “Complete” Simplifies Life for Primes

Our goal is to take as much of that workload off your plate as we can. When we deliver a complete subassembly, you reduce vendor logistics and eliminate a variety of tasks from your project.

Here’s a typical scenario: one of our current aerospace projects requires six different machined parts that are ultimately assembled. As a result, aerospace machining is only part of the job. It also includes tasks like sourcing hardware certified to aerospace standards, pressing alignment pins, installing threaded inserts, delicate assembly, and completing the certification package.

Because of our experience in subassembly services and our history as an AS9100 machine shop, these steps are relatively straightforward for our team. We’re set up to not only carefully assemble your products, but also procure certified hardware cost-effectively and maintain organized documentation. In the end, the subassembly can ship as a single delivery.

For a prime contractor or aerospace OEM, this creates significant time savings. Instead of diverting skilled resources to manage assembly or vendors, your team can stay focused on higher-value work.

Vendor Management Without the Risk

Of course, nearly every machine shop has to outsource some finishing and special processes as part of their workflow. But we manage those vendors on your behalf to simplify your logistics.

We have a large and trusted vendor network. And if your program requires an approved supplier list, we have extensive experience operating from those lists. But we also evaluate the vendors on your list ourselves, in some cases even visiting them to see their processes in person and determine where their strengths lie. By knowing which vendors to trust for which steps, we minimize a major risk of delay. And we believe that reduced timeline risk is a major benefit of our subassembly services.

Scheduling Discipline to Protect Delivery

A complete subassembly only simplifies your project if it arrives when you need it. That’s why we pay such close attention to our scheduling to keep projects on time.

We track each step in our ProShop ERP and schedule every process carefully, building in time for unexpected delays or complications. If a project begins to slip behind, we know weeks or months ahead of time because of our detailed scheduling.

When that happens, we don’t wait until the end of the job to inform you. We review options internally around scheduling and expedites, and if a risk remains, we communicate it early to collaborate on possible solutions.

Request a Quote for Subassembly Services

Complete subassemblies not only simplify your workflow and free time for high-value activities, but they also help you manage risk to your timeline if you choose the right manufacturing partner. If you’re looking for a partner that combines precision manufacturing, assembly capability, and vendor coordination, we’re ready to deliver on time.

Contact us today to discuss your next project with our Colorado machine shop!

Reliable 5-Axis Machining Services for Prime Contractors

At Focused on Machining, our 5-axis machining services and advanced scheduling allow us to expertly support prime contractors. We take on-time delivery performance seriously as your manufacturing partner because we know one late supplier can derail an entire production line. Currently, our on-time delivery rating sits at 95%.

Our 5-axis machining enables us to machine complex parts and serves as part of a larger system designed to reduce your risk and compress timelines.

5-Axis Machining: Complex Parts With Less Risk

5-axis machining is well known for handling complex geometry and features, but consistency is just as important for prime contractors. After all, many complex parts can be produced on 3-axis equipment, but the 3-axis option requires more setups and fixturing, introducing more chances for error.

Consider a part with multiple datums and a tight-tolerance hole that has to be located precisely relative to all of them. 3-axis equipment can achieve that result, but it depends on an expert machinist perfectly executing several flawless setups. Every additional setup introduces new risk.

With 5-axis machining, that same job can be completed in a single setup. Fewer setups mean better positional accuracy and a more repeatable process. That, in turn, will lead to fewer surprises during inspection and an overall more stable production and precision machining process.

Speed Scales With Automation

Speed is important in every industry, but for prime contractors, the large programs they often manage can make speed and reliability critical. Instead of waiting for a single order, you’re keeping a huge number of tasks on track.

Our five-axis not only reduces setup time, but it allows for extended runtime and lights-out operation, as well. That efficiency helps us protect lead times even when schedules get tight. The additional capacity also helps us adjust when the unexpected occurs, preventing disruption for your project and making us a perfect partner for contract manufacturing services.

A Process for Reliability in Every Step

When machine shops struggle with late deliveries, it’s rarely from any single mistake. Instead, they come from systemic process issues: no buffer for uncertainty, limited visibility in a schedule, and no technology to help recover from setbacks. If shops can’t recognize a problem until the due date arrives, you might be facing weeks or months until delivery.

We never want to put a customer in that position at Focused on Machining. We build realistic schedules in ProShop to account for not only the full scope of work but the inevitable bumps that happen in production. The scheduling is updated dynamically, allowing us to spot risks early and communicate with you to find solutions.

Our 95% on-time delivery rating does mean that a small percentage of our jobs ship late, but our process almost always allows us to measure those delays in days, not months. In part, that’s due to the modern equipment, like 5-axis machining, that we’re able to pair with our transparent scheduling technology.

Complexity and Dependability In One Shop

Prime contractors need dependable delivery just as much as they need complex parts, and we’re ready to provide both in our 5-axis machining services. Contact us today and partner with our Colorado machine shop for a low-risk manufacturing partner!

Why Our Credentials Give Prime Contractors Total Confidence

When prime contractors look for a dependable supplier and manufacturing partner, certifications and credentials are key aspects of their search. At Focused on Machining, our “credentials stack” makes us the perfect match for aerospace and defense partners. We’re able to meet rigorous standards and fill critical gaps for primes.

AS9100 Certification

AS9100 is an international quality management standard for aerospace and defense. We have been a certified AS9100 machine shop since 2021. (Note that this also incorporates ISO 9001:2015 certification.)

Achieving and maintaining this certification requires our entire operation to be audited regularly in areas like estimating, production, inspection, customer feedback, and more. We periodically undergo both full audits and surveillance audits. Full audits are particularly in-depth, performed by third-party auditors who scrutinize every detail.

The audits are rigorous, but we wouldn’t have it any other way. With such a challenging process, prime contractors can have confidence knowing our systems and processes meet proven high standards.

ITAR Registration

Focused on Machining is registered with the U.S. Department of State under ITAR (International Traffic in Arms Regulations). ITAR regulations govern how defense-related data is protected, shared, and more.

ITAR registration affects many parts of our daily operations. For instance, we restrict facility access and screen visitors to ensure only U.S. persons enter. (While ITAR does allow processes for non-U.S. persons to obtain access under certain conditions, we have chosen not to pursue that route to keep compliance simple.)

ITAR requirements also flow down to anyone touching controlled data, which means that subcontractors and partners must be compliant if we need to share ITAR-controlled data with them.

Certified Service-Disabled Veteran-Owned Small Business

Focused on Machining is proud to be a certified Service-Disabled Veteran-Owned Small Business (SDVOSB). Our owner, Justin Quinn, served in the U.S. Air Force, and our mission reflects his commitment to supporting the defense sector.

This designation used to require minimal documentation, but recent changes shifted the process, which we have successfully completed. As a result, we now hold a formal SBA certification that we are ready to share.

For customers with set-asides for SDVOSB, we can help you meet those targets while delivering the highest quality CNC machining services.

CMMC Level 2

Focused on Machining is also CMMC Level 2 compliant. We began our journey shortly after the framework was introduced in 2020 to be fully prepared when it first became a requirement.

Both because of our status as a veteran-owned business and our partnership with defense contractors, meeting these cybersecurity requirements has always been a priority. Our compliance reflects our commitment to upholding the highest standards of data security in support of national defense.

A Partner Built for Prime Contractors

Our certifications and credentials reflect our dedication to meeting the needs of our prime partners. When primes choose us, they gain a precision machining partner of the highest caliber capable of meeting your regulatory requirements and supporting your goals.

Request a quote today to partner with our Colorado machine shop!

5 Lessons Learned on Our Journey to CMMC Level 2 Compliance

By Justin Quinn, Owner of Focused on Machining

At Focused on Machining, we are fully prepared to support your CMMC Level 2 projects with our precision machining. But that compliance didn’t happen overnight.

When the CMMC framework was first announced, I knew how essential compliance would be for our customers involved in defense work. And as a veteran, that responsibility is personal to me. I quickly learned, however, that being among the first to tackle this challenge would come with unique challenges.

With the DoD beginning to enforce CMMC requirements, many shops are now facing the journey we’ve completed. To help other CNC machine shops, I want to share several lessons we learned along the way. I’ve also got one important recommendation for OEMs and primes navigating these early days of CMMC.

Why You Need an Experienced Partner

When the Department of Defense introduced the first version of the CMMC program in 2020, we immediately began investigating the certification process. At this time, no IT providers had any meaningful experience with the brand-new requirements, and the framework would continue to evolve for years to come.

Our existing IT provider was transparent about their lack of experience in the area, but they offered to help in any way they could. They had been trustworthy partners on other issues for many years, and I decided to take them up on their offer.

It quickly became clear that it would simply take too long to have a partner who was learning alongside me. I thanked them for their transparency and switched to a new IT company.

Lesson 1: If a partner tells you they’re not ready, it’s best to keep searching.

The Importance of Due Diligence

When we selected our second CMMC IT partner, they presented themselves as having deep CMMC expertise. At that point in time, it was still difficult to validate those types of claims, as everyone was still learning what CMMC would eventually become. With few established benchmarks or references available, we made the best choice we could at the time.

As the relationship continued, I began asking more detailed CMMC questions. Their responses were broad and vague, which made it clear their supposed expertise had just been in pursuit of sales.

Lesson 2: In the early days, it was hard to verify a potential partner’s expertise. Today, you have more available to you. Ask technical, requirement-based questions and request proof of prior CMMC work before choosing a partner.

Don’t Go It Alone

After my first two IT partnerships, I had made some progress on CMMC, but not enough. I briefly decided to handle CMMC myself. I love a challenge, and I’d previously led our certification efforts to become an AS9100 machine shop. I figured if I was intelligent enough to rebuild Air Force engines, I could handle this process.

But CMMC is different. The requirements are dense and technical, and some sections genuinely felt like reading a foreign language. I eventually decided I needed help from professionals.

Lesson 3: As a machine shop owner, you cannot effectively achieve CMMC Level 2 certification alone. Even if you’re strong in IT and have led other certification efforts, it’s simply a different beast.

Find the Right Partner and Work in Phases

At this point, I was committed to finding an experienced partner and doing extensive due diligence. I interviewed multiple firms that were able to provide clear proof of their expertise in CMMC.

Ultimately, I found the right partner in Imprimis in Colorado Springs. Their owner has decades of experience working with the DoD, and the firm specializes in CMMC work. They have been key to our success, and I recommend them to any other Colorado machine shop going through this process.

It’s important to note that, even after finding the right partner, the path to CMMC Level 2 certification is a marathon and not a sprint. Our process has included months of significant work followed by stretches of slower progress due to bottlenecks or reviews. That’s relevant to your expenses too, as some months will have significant costs, while others will be lower.

Lesson 4: Achieving CMMC certification takes place in stages, and it takes time. This structure helps distribute the spending and workload over time, but it also means the process is lengthy. Start early, well before a partner requires you to be certified.

What Primes Need to Know

These lessons have primarily been for other machine shops, but I do have a final message for our customers and primes. In many early CMMC contracts, Level 2 work begins with a self-assessed CMMC Level 2 status rather than a full third-party certification. But shops still must be actively progressing toward full Level 2 certification.

Lesson 5: If a shop says they are “almost done,” ask for proof. They should be able to provide documentation such as their scope outline, POA&M, system security plan, and other materials.

This matters for your supply chain, too. Even though we are compliant, we cannot send controlled documents to downstream vendors if they do not meet the necessary standards.

Moving Forward With Confidence

I’m sharing these lessons because I want to help other shops protect sensitive data and strengthen our national defense. Our journey was full of twists and turns, but we’re proud we achieved CMMC early.

If you are a machine shop owner who has questions, don’t hesitate to contact me.

And if you’re an OEM looking for a CMMC Level 2 manufacturer, request a quote today!