When you’re evaluating a manufacturing partner, there’s a long checklist to consider, from precision machining capabilities to certifications to quality control systems. These criteria often appear in audits or new customer interviews, and we’re proud to meet stringent requirements in all of these areas. But once the boxes are checked, how do you evaluate what can’t be captured in a spreadsheet?

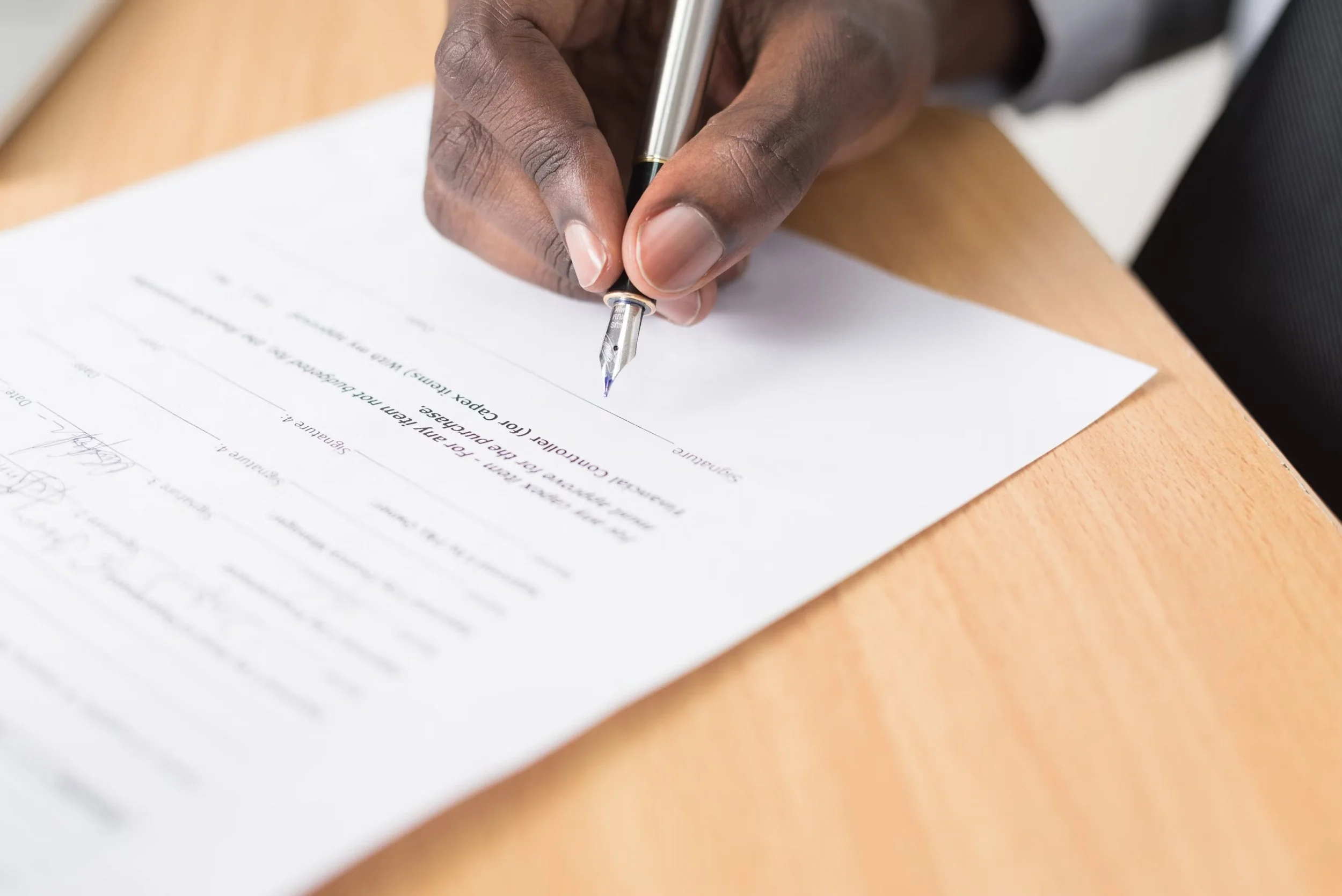

Contract manufacturing offers significant advantages for companies that need consistent part production over an extended period of time. These agreements can reduce costs by offering customers pricing at scale and minimizing administrative tasks. However, the cost savings of contract manufacturing can disappear quickly if you don’t choose the right precision machine shop as a partner.

At Focused on Machining, we’re proud of our work as an aerospace and defense machine shop because it’s personal for us. Our owner, Justin Quinn, spent six years in the United States Air Force, serving around the world as a C-17 aircraft mechanic. Now, Justin is passionate about supporting the men and women behind every mission in his work leading a CNC machine shop.

At Focused on Machining, we know that all of our customers are constantly searching for ways to improve their costs without compromising on quality. One strategy we often suggest is to consider our contract manufacturing services.

We have manufactured manifolds for many years at Focused on Machining, but recently, some of our aerospace machining customers have brought us increasingly sophisticated designs. These parts will be integrated into their fuel systems, and the complexity of these modern rocket parts has pushed our capabilities forward.

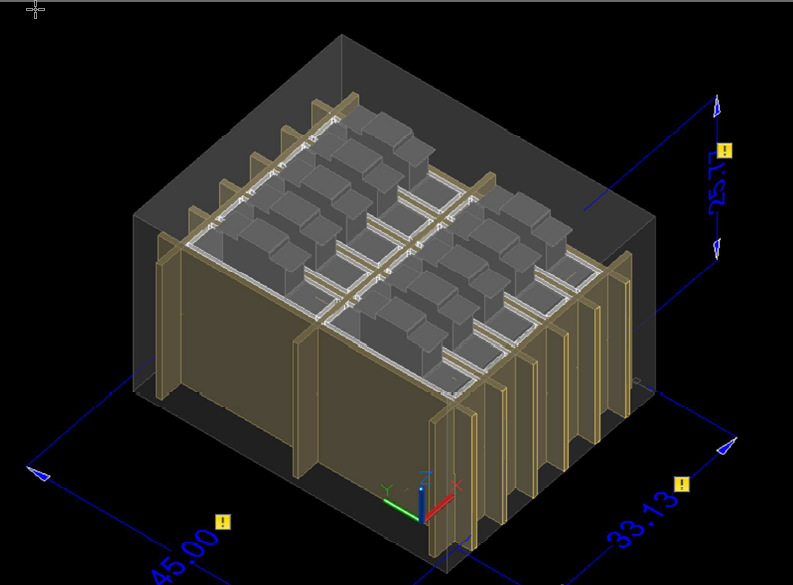

At Focused on Machining, we’ve spent years perfecting our lights-out capabilities as part of our production machining services. After all, even in this era of incredible automation and precision programming, it requires total confidence in your processes to leave high-value equipment running unattended while machining critical parts for trusted customers.

At Focused on Machining, we are dedicated to growing alongside our customers and consistently evolving to help them solve their newest challenges. After multiple customers approached us with requests for projects that included high-volume rivet and nut plate installation, we saw an opportunity to enhance our services while simplifying their supply chain.

Our Colorado machine shop has been steadily pursuing CMMC compliance for two and a half years now, and we’re entering the final phase of our journey. We aim to be CMMC compliant shortly, targeting audit readiness by the end of Q1.

Vendor-Managed Inventory (VMI) is a powerful tool to ensure you’re easily meeting your timelines. At Focused on Machining, our VMI program offers a strategic approach to managing part production that optimizes your costs and simplifies delivery.

By collaborating with Focused on Machining for both CNC machining services as well as your finishing needs, you’ll have a one-stop shop experience for your aluminum projects. Through our extensive network of expert finishing vendors, we deliver fully finished components tailored to your exact requirements.

At Focused on Machining, we take pride in our expertise in precision CNC machining, which encompasses a diverse range of materials. Our skilled operators, paired with cutting-edge technology, enable us to produce high-quality parts from aluminum, steel, stainless steel, copper, brass, plastic, and more.

At Focused on Machining, customer satisfaction guides our actions every day and we’re constantly striving to elevate our performance. To measure our progress, we recently conducted a survey to gather feedback from our clients on key areas like customer service, product quality, and delivery times.

At Focused on Machining, our name reflects our precision machining expertise, but our focus extends far beyond that. Every step of the customer experience matters to us, from initial communication to machining to shipping. Delivering your parts on time and in perfect condition is a key part of our process. That’s why we’ve introduced custom foam packaging and reusable shipping crates for specific projects. This new shipping option offers better protection, more cost efficiency, and a smoother overall experience for our customers.

As Veteran’s Day approaches next month, I want to share the story of my journey from the Air Force to owning Focused on Machining, a precision CNC machine shop in Colorado. For many veterans, finding the right path after service can feel daunting, but I believe my experience can help offer a potential roadmap. My journey from military aircraft maintenance to running a manufacturing business has been deeply rewarding and I encourage veterans to explore opportunities in this field as they transition to civilian life.

At Focused on Machining, we bring years of expertise across a wide range of materials such as stainless steel, titanium, Monel and Inconel. Here, we’re focusing on our experience with 7000 series aluminum, a strong alloy that’s a popular material choice in a variety of industries.

We’ve talked in the past about how long-term manufacturing contracts benefit customers in the right circumstances. And among long-term contracts, certain scenarios will offer even more savings. One of the most notable is working with us on a “family of parts,” a set of similar parts that we can machine at significantly reduced pricing.

If you’re looking for manufacturing partners who can help you meet FAR requirements, I hope you’ll consider Focused on Machining for CNC machining services. We have a reputation for machining complex parts fast and at an incredibly high quality level

Focused on Machining offers lights-out machining as part of our CNC production machining services. These capabilities allow us to run orders around the clock so we can provide faster lead times, lower costs, and better flexibility.

When you order repeat parts from a CNC machine shop, you can’t be fully confident the parts will be consistent from one order to the next until you understand the shop’s approach to documentation. At Focused on Machining, we have a fully digitized solution that allows us to offer unbeatable consistency and efficiency when it comes to repeat orders. Like many of our other solutions to manufacturing challenges, it all ties back to our ERP system.

Building complex assemblies requires more than having the right capabilities and expertise on the precision machine shop floor. It’s just as important to have the right software working behind the scenes to facilitate the process.

Running a precision machine shop during an industry-wide labor shortage, a global pandemic, unprecedented supply chain disruptions, and some of the most contentious presidential election cycles in history has certainly been one of the most interesting challenges of my life.

Customers are often shocked at how quickly our CNC machine shop can turn around an impressively detailed and accurate quote for a complex assembly. Our secret? Our advanced digital quoting software. If you’re wondering what goes on behind the scenes, here’s a peek behind the curtain.

At our Colorado CNC machine shop, we primarily machine Inconel for rocket jet engine components. We’re adept at machining the many different grades of Inconel, though we mostly work with Inconel 625 and Inconel 718.

Our Colorado CNC machine shop is in the process of pursuing CMMC 2.0 compliance, which will prove to the US Department of Defense that we meet rigorous cybersecurity standards. Now that we’re several months into the process, we’re here to provide an update on our status—because transparency and accountability matter to us.

A recent trend in aerospace machining is that parts are becoming so complex that traditional equipment and approaches are no longer sufficient. Aerospace buyers often need parts with exceptionally tight tolerance features on opposite or multiple sides, which can be difficult to achieve with a standard CNC mill. At Focused on Machining, we’ve found great success leveraging multi-axis machining with zero-point fixturing to take on the most challenging aerospace machining jobs.

If you find yourself placing repeat orders for the same parts multiple times in a year, consider establishing a long-term contract with your manufacturing partner. Not all shops provide contract manufacturing services, but those that do are almost always open to discussing this option with customers. That’s because long-term contracts benefit buyers and precision machine shops alike.

One of the most important truths in manufacturing is that you get what you pay for—from production machining services to secondary processes like plating. Just as machine shops' costs and lead times vary depending on capabilities, certifications, and quality, so is the case for plating vendors.

Many shops view source inspections as a necessary evil. Source inspections can indeed be cumbersome for shops whose processes are still mostly manual—there’s no denying that. Fortunately, at Focused on Machining, our robust ERP system allows us to facilitate source inspections easily. In fact, we’ve even come to really appreciate source inspections and the customers who require them.

Reducing the costs of machined parts can be as easy as having a conversation: always communicate with a shop about your purchasing intentions. If you plan to place a particular order on a recurring basis, the right contract manufacturing services partner can talk to you about opportunities to obtain the best costs over time with a long-term contract.

You get what you pay for in manufacturing. Unfortunately, many buyers learn this lesson the hard way—something we’ve seen firsthand at our AS9100 machine shop. We’re happy to work with buyers now to get them the parts they need. But imagine the time, money, and stress they could have saved by having us machine their parts in the first place.