Since hitting the market in the 1930s, Inconel®—a group of nickel-based superalloys—has become a popular material for oil and gas, US Navy submarine, and jet engine components that benefit from its exceptional strength, corrosion resistance, and heat resistance.

Inconel has a low coefficient of thermal expansion at 77 degrees Fahrenheit to 1,400 degrees Fahrenheit, meaning it can withstand extreme heat and extreme temperature ranges without changing its size.

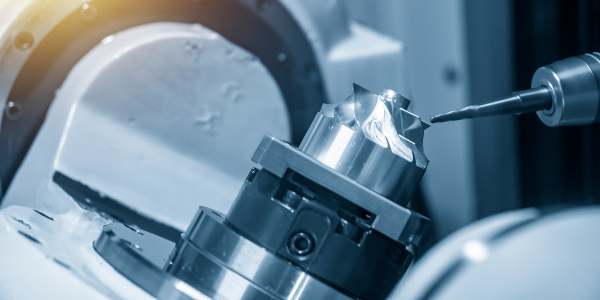

At our Colorado CNC machine shop, we primarily machine Inconel for rocket jet engine components. We’re adept at machining the many different grades of Inconel, though we mostly work with Inconel 625 and Inconel 718.

Inconel 625 vs. 718

Inconel 625 and 718 have slightly different compositions. Inconel 625 comprises nickel, chromium, molybdenum, and niobium, while Inconel 718 comprises nickel, chrome, iron, and niobium.

Both grades offer exceptional corrosion resistance, though 718 has a higher strength. Inconel 625 is generally easier to machine because although it is prone to chatter, it is not prone to work hardening to the same degree as 718. Work hardening occurs when worn-down tools mush the material, creating friction and adding heat, which makes the hard material even harder. Work-hardened Inconel 718 may become so hard that it’s nearly impossible to cut.

In other words, if your application doesn’t require the higher strength of Inconel 718, you can save money by selecting the easier-to-machine 625.

When customers ask for Inconel 718, our Colorado CNC machine shop typically works with AMS 5662 and 5663. AMS 5662 is the rawest and softest state of 718, which is how we prefer to machine it. AMS 5662 can be heat treated to 5663, a harder state of the alloy, though we wait until after machining it to bring it to this condition.

Need Inconel Parts? Follow These Tips

Getting parts made from specialty alloys like Inconel isn’t as straightforward as getting parts made from a standard material like aluminum. If you need Inconel machining, follow these tips for the best experience.

1. Work with a shop that specializes in Inconel machining

It takes a skilled machinist to effectively machine Inconel. With a material like aluminum, machinists can make big, deep cuts to remove a significant amount of material quickly. In contrast, Inconel requires smaller, lighter, faster cuts to avoid work hardening. Our Colorado CNC machine shop has mastered the art of machining Inconel.

In addition to meticulously cutting the material, shops must have the right tooling for machining Inconel. At Focused on Machining, we work closely with our tooling vendors to select tooling with special wear-resistant and heat-resistant coatings. We then dedicate that tooling exclusively to machining Inconel.

2. Be wary of the lowest quote

If five shops quote your Inconel job, and one shop quotes you significantly lower than the others, think twice before working with them. A suspiciously low quote often indicates that a shop might not have the proper experience machining Inconel to anticipate the challenges they’ll encounter with the material. In these cases, there’s a high risk that something will go wrong, delaying your lead time.

3. Anticipate material sourcing challenges

With materials in short supply, we always encourage customers to act fast by placing an order shortly after receiving a quote. This advice is especially important for Inconel, one of the more difficult materials to source.

4. Call out the right AMS specification

It’s not uncommon for engineers to call out a plate spec for a round part, prompting back-and-forth communication with a shop that can delay the start of the project. In most cases, engineers approve the use of a different spec, but by then, time has already been lost.

If you absolutely need a plate spec for a round part, we can use it, but keep in mind that your costs will increase because we’ll need to remove more material.

When you need Inconel machining, you can count on Focused on Machining. Request a quote today.