Many shops view source inspections as a necessary evil. Source inspections can indeed be cumbersome for shops whose processes are still mostly manual—there’s no denying that.

Fortunately, at Focused on Machining, our robust ERP system allows us to facilitate source inspections easily. In fact, we’ve even come to really appreciate source inspections and the customers who require them.

The Role of Source Inspections in Defense and Aerospace Machining

Source inspections are a common requirement among large aerospace and defense companies like Lockheed Martin and United Launch Alliance that deal with mission-critical parts. When a shop completes a precision machining order, the company will send a quality representative to its facility to confirm that the parts meet all specifications before they are shipped.

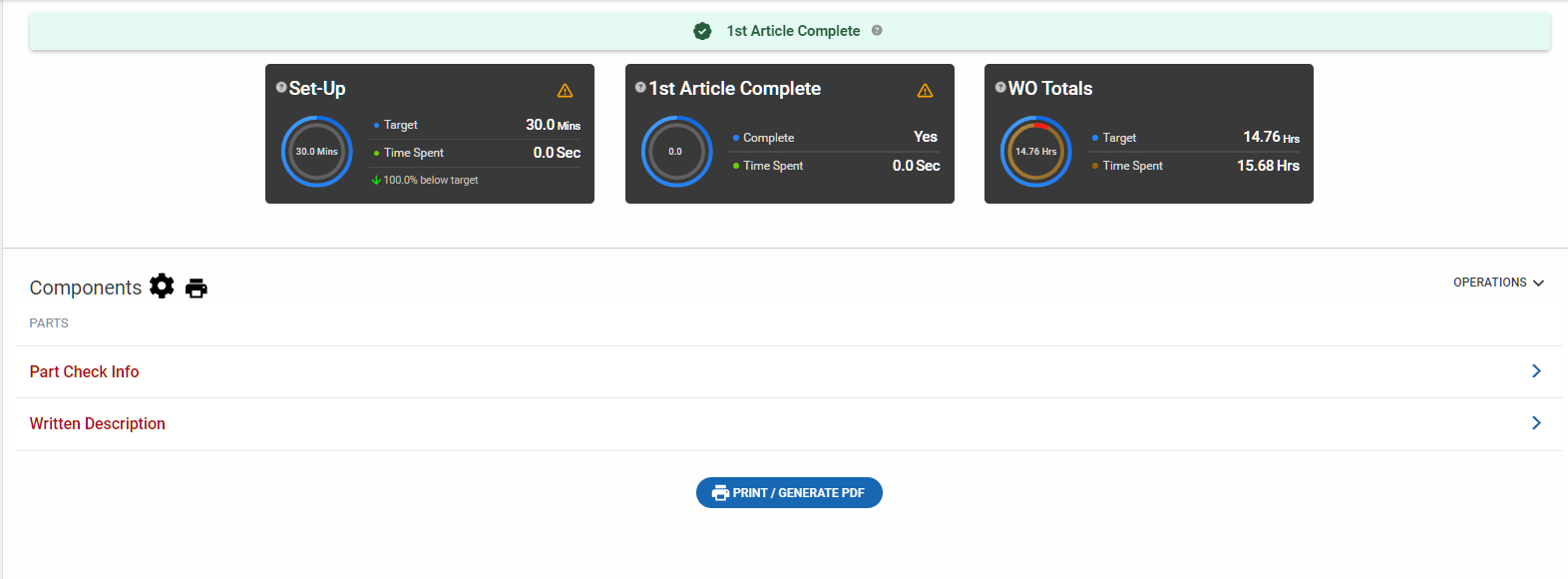

The source inspector will review the parts’ documentation (e.g., material certifications, plating certifications, print, inspection results) and conduct their own quality control inspections or ask the shop to demonstrate how their quality control team inspected the parts.

The goal is to identify issues proactively and prevent the lengthy back-and-forth that can occur when those issues are identified after the parts reach the customer. At Focused on Machining, we view this benefit as a win-win for shops and customers alike. While source inspections slow the process down initially, we appreciate knowing that once a source inspector has signed off on a job, those parts won’t return to us for additional work.

How Our ERP System Enables Easy Source Inspections

Documentation is an essential part of a source inspection—and that’s where many shops struggle.

For example, one of our customers requires that we upload our documentation to one website and use a different website to schedule a call. This company’s source inspector prefers to review the documentation virtually before coming for an on-site visit. We can then correct any issues so that by the time the source inspector arrives at our facility, chances are high that they’ll approve the parts that day.

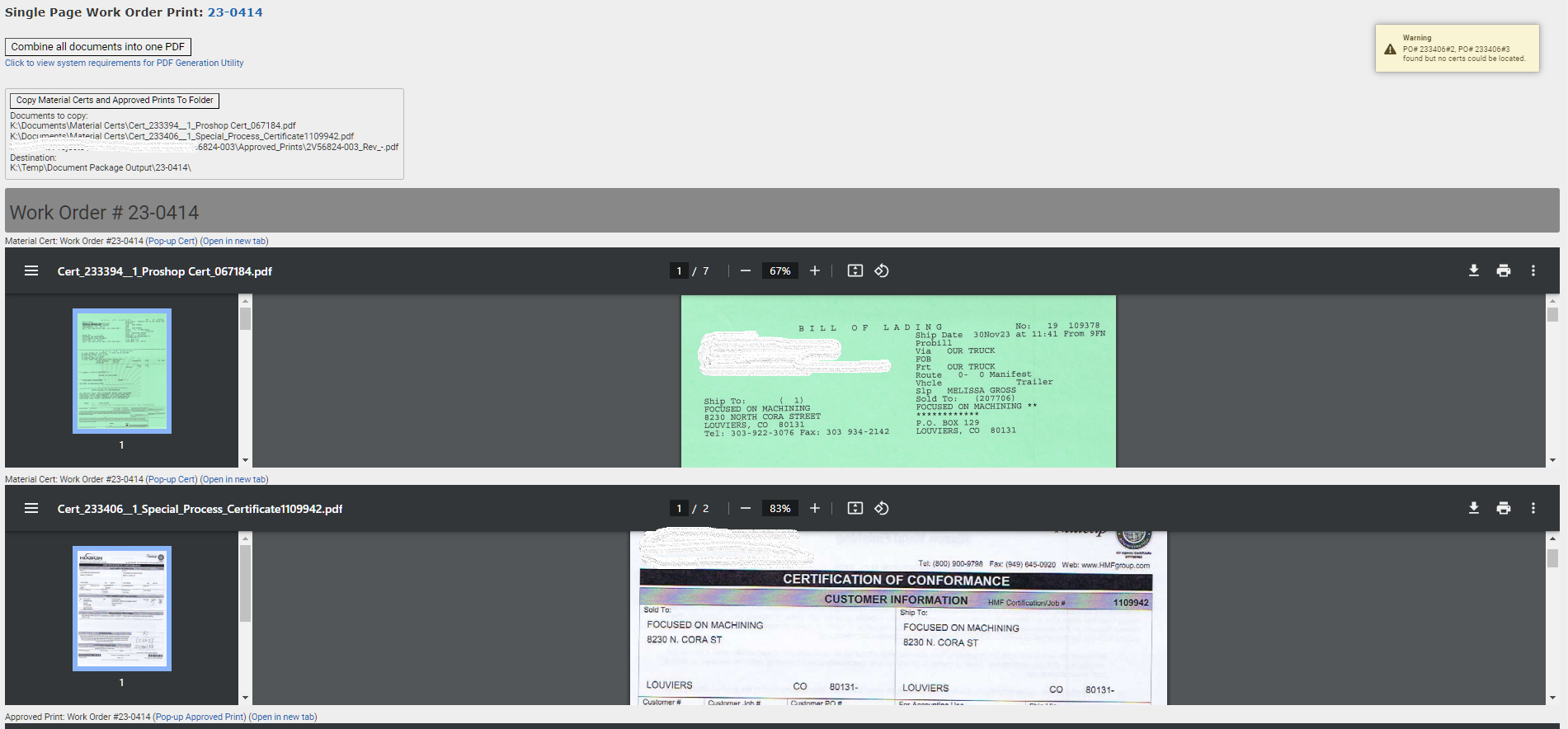

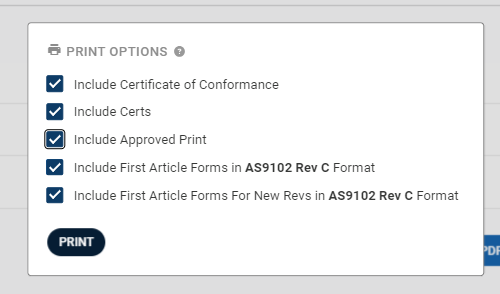

Understandably, shops with manual documentation processes can find it challenging and time-consuming to locate material certifications, plating certifications, prints, inspection results, and more and combine all that information in one neat package. But with our ERP system, this process is as easy as clicking a button. The system pulls the necessary information from different documents we’ve already uploaded and packages it together for us to save in a clearly labeled folder.

Source inspectors who have worked with our shop for defense and aerospace machining orders appreciate that they receive one file with all information organized in a sensible manner.

Want a Source Inspection? Let Us Know During Quoting

If you need a source inspection for your next defense or aerospace machining order, Focused on Machining is more than happy to accommodate you. We simply ask that you let us know during quoting so we can build a source inspection into our timeline and quote your lead time accurately.

Even if you don’t require an official source inspection, you’ll receive the same documentation package we deliver to companies that do. That’s because our commitment to providing stellar service extends to every customer we work with.

Request a quote for defense or aerospace machining services!