Zero-Point Fixturing: Our Approach to Complex Aerospace Machining Job

A recent trend in aerospace machining is that parts are becoming so complex that traditional equipment and approaches are no longer sufficient. Aerospace buyers often need parts with exceptionally tight tolerance features on opposite or multiple sides, which can be difficult to achieve with a standard CNC mill.

5-axis and multi-axis machining have emerged as gold-standard solutions for machining these parts, enabling shops to achieve the precision and efficiency required to feel confident quoting them.

At Focused on Machining, we’ve found great success leveraging multi-axis machining with zero-point fixturing to take on the most challenging aerospace machining jobs.

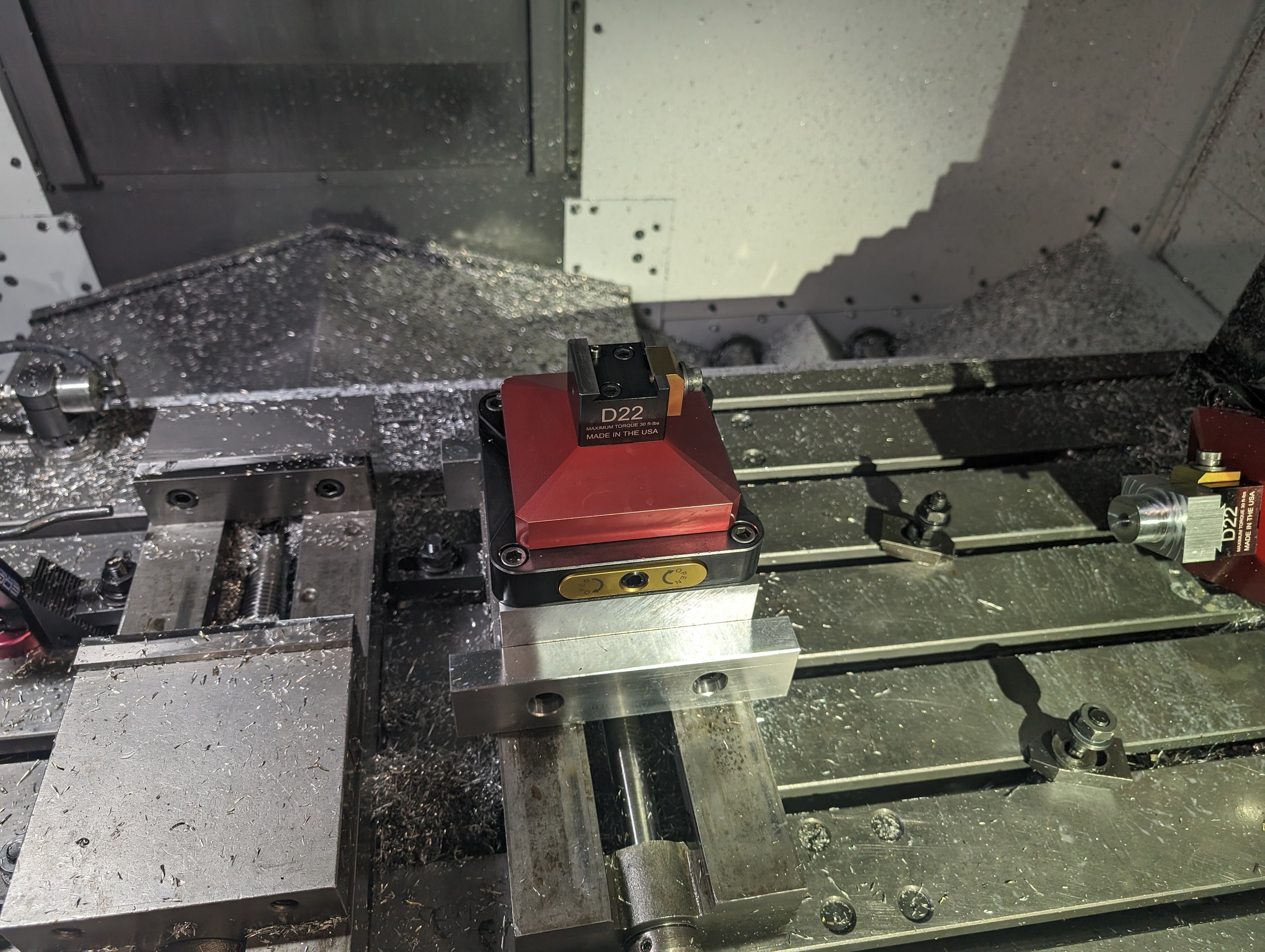

Our Shop’s Zero-Point Fixturing Solution

We invested in a RockLock base permanent fixturing setup for each of our multi-axis machines. The RockLock base allows us to swap vises and fixtures quickly with no setup time and guarantees repeatability of less than 0.0003”.

Here’s a comparison of how a complex aerospace machining job would proceed without zero-point fixturing vs. how it proceeds with zero-point fixturing.

Aerospace machining without zero-point fixturing

Let’s say we’re machining a tight tolerance part with three operations using a traditional setup without zero-point fixturing. Operation 1 is easy enough because we’re just machining raw stock to establish the datums from which Operation 2 and 3 will be measured.

However, once we get to Operation 2, things become more complicated. Let’s say we need to flip the part upside down or sideways to machine a different side. If the tolerances are exceptionally tight, the machinist will need to reposition the part and use a manual indicator to orient it perfectly in the machine. The machinist will then need to do the same thing with every single part in the order, which, as you can imagine, makes for an incredibly inefficient process.

This approach may be feasible if there are only 5-10 parts in an order. But most shops can’t justify having a machinist perform this degree of manual work for higher-volume orders—and the cost of doing so would make buyers’ jaws drop.

Aerospace machining with zero-point fixturing

With zero-point fixturing, the extensive manual work is eliminated. The vise enters a base that has pins in it with precise locating capabilities. We machine Operation 1 in that vise in one location to achieve all the Operation 1 features. Then, we take the entire vise up and out of the machine and move it to the Operation 2 fixture. The machine knows exactly where that part is within 0.0001” from Operation 1. No manual indicating is required, allowing us to work much more efficiently. Once we have proven the first part, we can machine multiple parts in the same setup.

Quality control

Even quality control is more efficient with zero-point fixturing. We have a RockLock base in our quality department, so if we program everything from the center of the vise—including the CMM—we can take the whole vise and part out of the machine, move it over to quality, and it will repeat there within 0.0001”. The quality department can run its program without spending time locating the part. If a change is required, we move the vise and part back to the machine and quickly make adjustments.

Meeting the Evolving Needs of the Aerospace Industry

As an AS9100 machine shop, Focused on Machining is committed to meeting the evolving needs of the aerospace industry. Multi-axis machining with zero-point fixturing allows us to take on complex jobs with the same precision and efficiency as 5-axis machining.

We love a good challenge, so don’t be afraid to approach us with your toughest aerospace machining requirements. Request a quote today!