You get what you pay for in manufacturing. Unfortunately, many buyers learn this lesson the hard way—something we’ve seen firsthand at our AS9100 machine shop. We’re happy to work with buyers now to get them the parts they need. But imagine the time, money, and stress they could have saved by having us machine their parts in the first place.

The Importance of Investing in a High-Quality Prototype

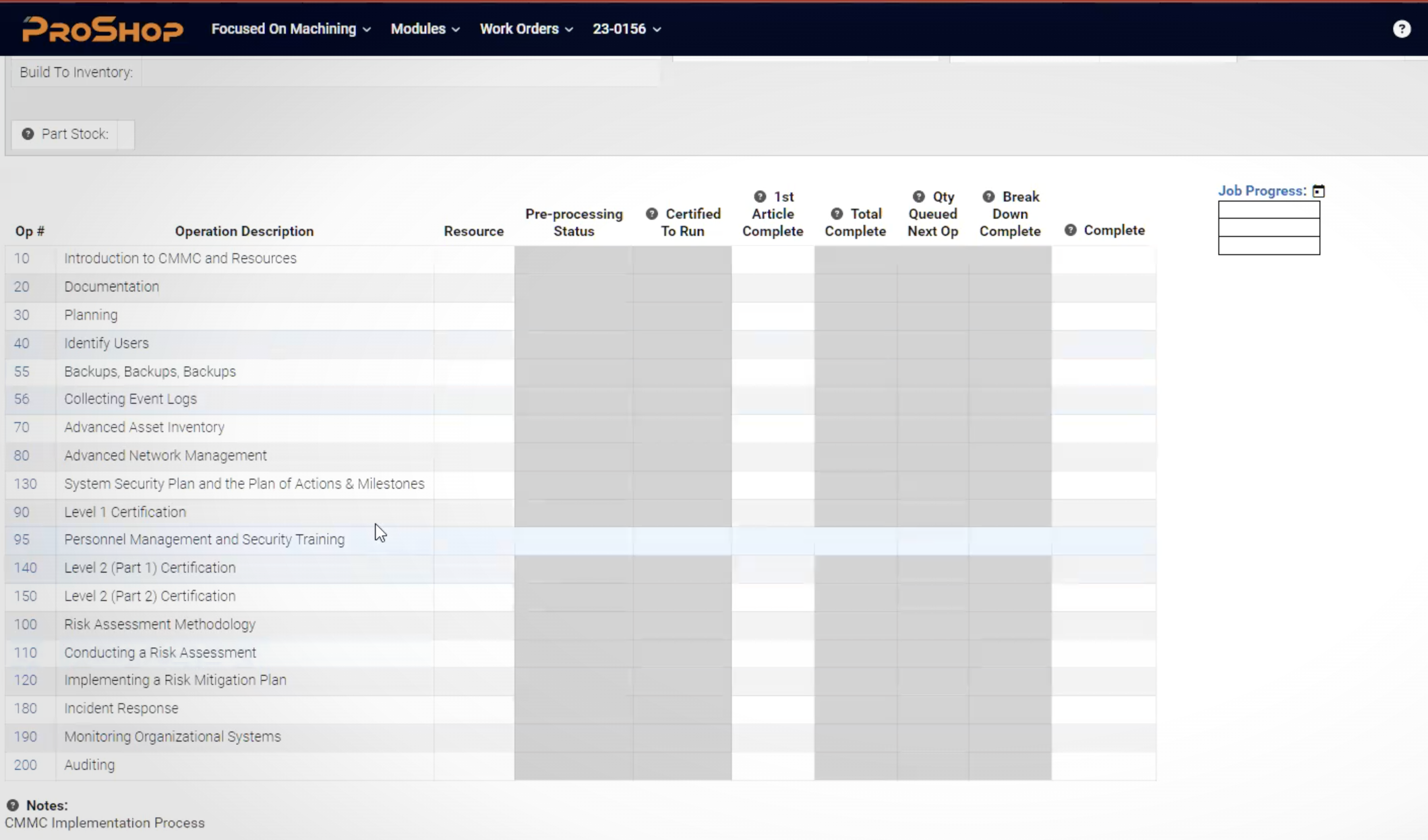

A Game-Changing Approach to Achieving CMMC 2.0 Compliance

Any manufacturer pursuing CMMC 2.0 compliance will tell you that the process is rigorous, to say the least. Focused on Machining is currently working to achieve Level 2 certification, which has a long list of 110 requirements aligned to NIST SP 800-171. We anticipate that our journey to CMMC certification will take us a total of 18 months when all is said and done.

Improving Precision and Efficiency with Multi-Axis Machining

As an aerospace machining shop committed to innovation and continuous improvement, it was only a matter of time before we progressed from standard CNC milling to multi-axis machining. Keep reading to learn how our multi-axis machining capabilities empower us to deliver unparalleled precision and efficiency, setting us apart from other shops offering contract manufacturing in Colorado.

Our Journey to CMMC Certification: How We Protect Your CUI

It’s Time to Break the Cycle of Over-Tolerancing Parts

While a tolerance of +/- 0.0005” was once considered tight, we now regularly see prints with microscopic tolerances down to +/- 0.0001”. For visual context, a +/- 0.0003” tolerance is like taking a piece of hair, which is about 0.003”, slicing it into ten pieces, and having one of those pieces represent the permitted variance.