When you need an assembly, you have a couple of standard options:

Source the parts from multiple precision machine shops, and build your assembly in-house.

Source all the parts from one precision machining partner and have them build your assembly for you.

Buyers often choose option #1 because they assume it’s the most cost-effective solution. Maybe they source the complex parts from one shop and find a less expensive shop to machine the simpler parts so that they can secure the lowest total cost per part. Then they can have their own people assemble the parts in-house to save even more money—or so they think.

As a precision machine shop that has worked with many customers over the years, we have a different perspective on assemblies. We know the risks involved with sourcing assembly parts from more than one shop and that relying on a single shop for turnkey assembly services often saves customers time and money in the long run.

At Focused on Machining, we can:

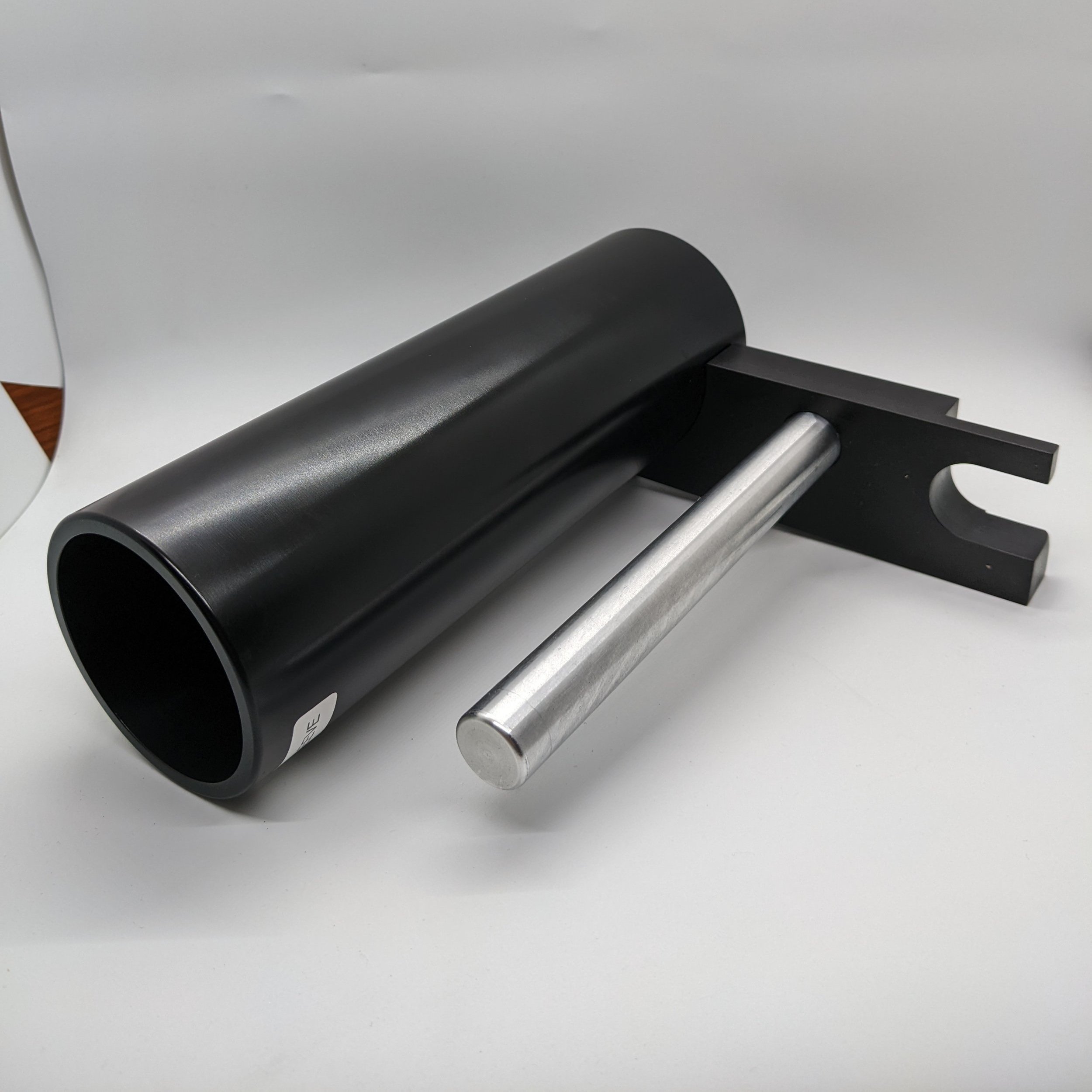

Machine all the necessary parts for your assembly

Purchase and install hardware components

Build your assembly and ship it to you in perfect working condition

Let’s explore some benefits of choosing us as your precision machining partner for completed assemblies.

Proactive Fit, Form, and Function Testing

Sourcing assembly parts from the same precision machine shop is especially important when dealing with tight tolerances on overlapping parts. For instance, if Part A fits into Part B, it’s possible that both parts could be machined to specifications but still not fit together in the final assembly.

If you source those parts from different shops, you won’t be aware of this potential problem until you receive the parts at your facility and can’t get them to fit. Now you’re going to lose time and money having the parts redone.

When you entrust one precision machining partner with your entire assembly, that shop can conduct fit, form, and function tests as they go to proactively fix any issues and ensure that you receive a functioning assembly.

Hardware Purchasing and Installation

Machined parts aren’t the only factors to consider when building an assembly. There are also hardware components that must fit perfectly. A poor hardware fit or installation can result in a damaged part that could take weeks to get fixed. Fortunately, a full-service precision machine shop like Focused on Machining can purchase and install hardware for you.

Press pins

Press pins typically have tight tolerance fits, so it’s best to have a machine shop insert this hardware. We buy the pins ourselves and measure them carefully when they arrive to confirm that they are in spec. If they aren’t, we may adjust how we machine the part to ensure a successful press.

Sometimes, customers over-tolerance press pin holes to where it’s almost impossible to press in the pin without damaging the part or the pin itself. When we’re building the assembly, we notice these issues and make any necessary adjustments.

Heli-Coils®

It’s easy to damage a threaded hole when trying to install a Heli-Coil. If that damage occurs at your facility, it could take weeks to get the hole fixed. If it occurs in our precision machine shop, we simply retap the hole, reform the threads, and properly install the Heli-Coil.

Adhesives and sealants

Some of our customers request that the inserts installed into their parts are sealed. In these cases, we can buy the adhesives or sealants, apply them properly, and install the hardware.

Trust Our Precision Machine Shop for Turnkey Assembly Services

When you trust Focused on Machining to provide turnkey assembly services, you significantly reduce the potentially costly risks associated with sourcing assembly components from more than one shop. You also free up your internal employees from having to build assemblies so that they can direct their labor elsewhere.

Still skeptical that you’ll save time and money with Focused on Machining’s assembly services? Let’s talk about your project. If you have an assembly you’d like to discuss, reach out, and we’ll let you know what we can do for you.